Coordinated disposal of fly as…

Suzhou JoyFa Environmental Technology Corp. Ltd.

National Hotline: 0512-68653260

Project name: Zero discharge of wastewater from steel industry

Customer unit: Hesteel Group

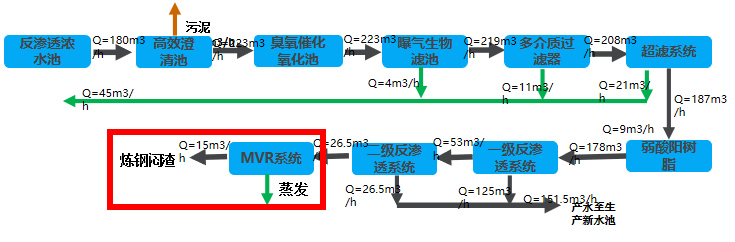

Scheme design: High efficiency clarifying tank + ozone catalytic oxidation tank + multi-media filtration +UF+RO+MVR